The P336/36, P336/37, P336/5, P336/6, P336/4, P336/9, P336/25, P336/26, P336/27 and P336/28 series trailed sprayers are used for performing chemical plant protection treatments in field crops, as well as mineral plant fertilisation procedures. Attached to the bottom three-point hitch of a tractor,

the trailed sprayers are equipped with 1200, 1500, 2000, 2500 or 3000 l tanks, and with 15m or 18m spray booms.

Read more

2500 l, 3000 l, 2500 l and 4000 l trailed sprayers with 15 m to 24 m spray booms The P336/11, P336/12, P336/13, P336/14, P336/15, P336/16, P336/17, P336/18, P336/19, P336/20, P336/21, P336/22, P336/23, P336/24, P336/29, P336/30, P336/31, P336/32, P336/33, P336/34 and P336/35 series trailed sprayers are used for performing chemical plant protection treatments in field crops, as well as mineral plant fertilisation procedures.

The trailed sprayers are equipped with 2500, 3000 or 4000 l tanks and 15 m to 24 m wide spray booms.

Read more

The P161, P161/1, P161/4 and P161/5 type mounted sprayers are used for performing chemical plant protection treatments in field crops, as well as mineral plant fertilisation procedures involving liquid mineral fertilisers.

The mounted sprayers are equipped with 400 l or 600 l tanks and 10 m or 12 m spray booms.

Read more

The P161/3, P161/6, P161/7, P161/8, P161/9 and P161/10 type mounted sprayers are used for performing chemical plant protection treatments in field crops, as well as mineral plant fertilisation procedures involving liquid mineral fertilisers.

The mounted sprayers are equipped with 600, 800 or 1000 l tanks and with 15m or 18m spray booms.

Read more

AGROSA mounted cup planters for seedlings: the double-row S237/3, triple-row S237/5 and quadruple-row S237/4 models are designed for planting all kinds of seedlings from multi-plant cultivation. Rootage size should not exceed 50 mm. The planting of seedlings can take place at any inter-row width starting from 55 to 140 cm for the double-row planter S237/3, from 35 to 70 cm for the triple-row planter S237/5, and from 55 to 83 cm for the quadruple-row planter S237/4. Plant spacing in a row ranges from 15 to 225 cm.

In the vegetable industry, planters are used for planting vegetables and fruit seedlings, including cabbage, lettuce, celery, tomato, strawberry pepper tobacco fodder beet and herbs. In horticulture

and forestry, they are used for establishing nurseries, including rose, shrub, spruce tree or pine tree nurseries.

Read more

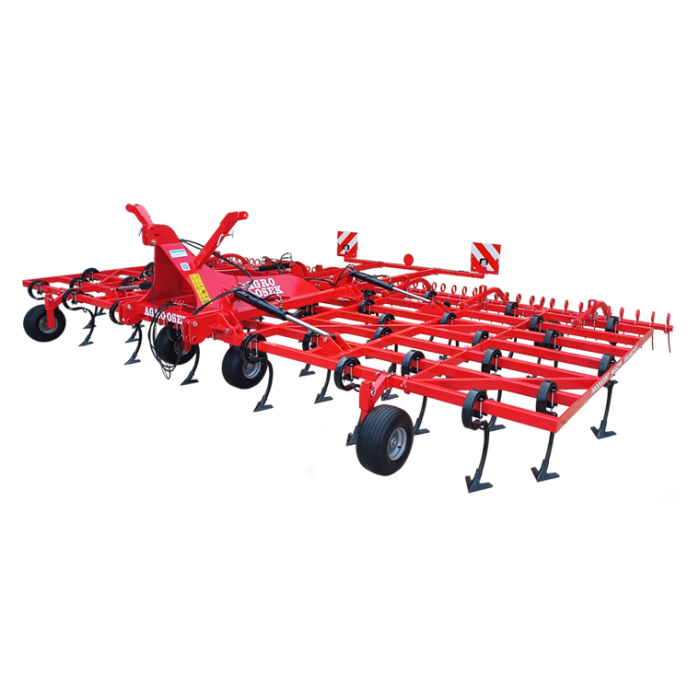

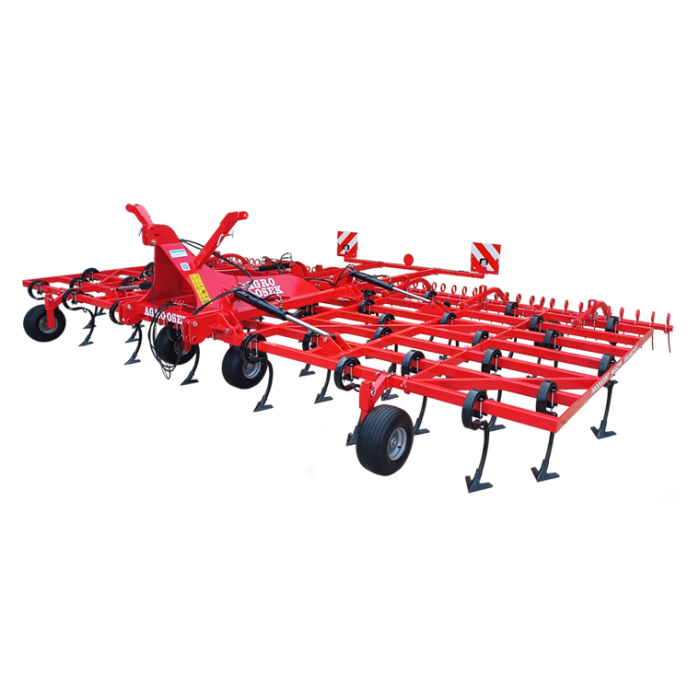

<p id="tw-target-text" class="tw-data-text tw-text-large tw-ta" dir="ltr" data-placeholder="Tłumaczenie" data-ved="2ahUKEwiv_besgpqKAxW7VfEDHY8IPPQQ3ewLegQICxAT" aria-label="Przetłumaczony tekst: The stubble cultivator is intended for post-harvest soil cultivation. The machine is used for effective mechanical destruction of weeds and self-seeding plants and simultaneous preparation of the ground for no-till sowing. The cultivator's teeth end with goose feet. Recommended working depth up to 15cm."><span class="Y2IQFc" lang="en">The stubble cultivator is intended for post-harvest soil cultivation. </span></p>

<p class="tw-data-text tw-text-large tw-ta" dir="ltr" data-placeholder="Tłumaczenie" data-ved="2ahUKEwiv_besgpqKAxW7VfEDHY8IPPQQ3ewLegQICxAT" aria-label="Przetłumaczony tekst: The stubble cultivator is intended for post-harvest soil cultivation. The machine is used for effective mechanical destruction of weeds and self-seeding plants and simultaneous preparation of the ground for no-till sowing. The cultivator's teeth end with goose feet. Recommended working depth up to 15cm."><span class="Y2IQFc" lang="en">The machine is used for effective mechanical destruction of weeds and self-seeding plants</span></p>

<p class="tw-data-text tw-text-large tw-ta" dir="ltr" data-placeholder="Tłumaczenie" data-ved="2ahUKEwiv_besgpqKAxW7VfEDHY8IPPQQ3ewLegQICxAT" aria-label="Przetłumaczony tekst: The stubble cultivator is intended for post-harvest soil cultivation. The machine is used for effective mechanical destruction of weeds and self-seeding plants and simultaneous preparation of the ground for no-till sowing. The cultivator's teeth end with goose feet. Recommended working depth up to 15cm."><span class="Y2IQFc" lang="en">and simultaneous preparation of the ground for no-till sowing. </span></p>

<p class="tw-data-text tw-text-large tw-ta" dir="ltr" data-placeholder="Tłumaczenie" data-ved="2ahUKEwiv_besgpqKAxW7VfEDHY8IPPQQ3ewLegQICxAT" aria-label="Przetłumaczony tekst: The stubble cultivator is intended for post-harvest soil cultivation. The machine is used for effective mechanical destruction of weeds and self-seeding plants and simultaneous preparation of the ground for no-till sowing. The cultivator's teeth end with goose feet. Recommended working depth up to 15cm."><span class="Y2IQFc" lang="en">The cultivator's teeth end with goose feet. Recommended working depth up to 15cm.</span></p>

Read more

Mounted planters for seedlings: the double-row S23, triple-row S237/2 and quadruple-row S237/1 models are designed for planting all kinds of potless seedlings 6 to 20 cm high in field crops. The planting of seedlings can take place at any inter-row width starting from 30 cm.

In the vegetable industry, planters are used for planting vegetables and fruit seedlings, including cabbage, lettuce, celery, tomato, pepper, strawberry, tobacco, fodder beet, etc. In horticulture and forestry, they are used for establishing nurseries, including rose, shrub, spruce tree or pine tree nurseries.

Read more

Hydraulically folded tooth field harrows are used for shallow topsoil loosening, levelling the soil surface after ploughing, crushing and breaking up soil clods, removing weeds and grass-sod, extracting couch grass from the soil, mixing mineral fertilisers into the soil, and performing other field work.

Tooth field harrows are produced in working widths of 5.6 m, 6.7 m and 8.4 m.

Read more

Hydraulically folded tooth field harrows are used for shallow topsoil loosening, levelling the soil surface after ploughing, crushing and breaking up soil clods, removing weeds and grass-sod, extracting couch grass from the soil, mixing mineral fertilisers into the soil, and performing other field work.

Tooth field harrows are produced in working widths of 5.6 m, 6.7 m and 8.4 m.

Read more

Hydraulically folded tooth field harrows are used for shallow topsoil loosening, levelling the soil surface after ploughing, crushing and breaking up soil clods, removing weeds and grass-sod, extracting couch grass from the soil, mixing mineral fertilisers into the soil, and performing other field work.

Tooth field harrows with front bars and track looseners are produced in working widths of 5.6 m, 6.7 m and 8.4 m.

Read more

Hydraulically folded tooth field harrows are used for shallow topsoil loosening, levelling the soil surface after ploughing, crushing and breaking up soil clods, removing weeds and grass-sod, extracting couch grass from the soil, mixing mineral fertilisers into the soil, and performing other field work.

Tooth field harrows with rollers are produced in working widths of 5.6 m, 6.7 m and 8.4 m.

Read more

BEE is a multi-purpose strip-till unit for loosening, fertilising and sowing procedures performed at one operation.

Strip till involves loosening those soil strips where seeds will later be sown. The remaining soil strips are usually left uncultivated, covered with crop residues

or green manure from crop cover. In addition, during strip till, the fertiliser is dosed precisely into the soil layers, under the seeds.

BEE is a unit mounted on the rear three-point hitch of a tractor, with an option of aggregating a seed drill or sowing sections with it.

Owing to the adjustable row spacing, the unit can be used to sow maize, oilseed rape, sugar beet, cereals, etc.

Read more

HORNET is a multi-purpose strip-till unit for loosening, fertilising and sowing procedures performed at one operation.

Strip till involves loosening those soil strips where seeds will later be sown. The remaining soil strips are usually left uncultivated, covered with crop residues

or green manure from crop cover. In addition, during strip till, the fertiliser is dosed precisely into the soil layers, under the seeds.

HORNET is a unit mounted on the rear three-point hitch of a tractor, with an option of aggregating a seed drill or sowing sections with it.

Owing to the adjustable row spacing, the unit can be used to sow maize, oilseed rape, sugar beet, cereals, etc.

Read more

WASP is a multi-purpose strip-till unit for loosening, fertilising and sowing procedures performed at one operation.

Strip till involves loosening those soil strips where seeds will later be sown. The remaining soil strips are usually left uncultivated, covered with crop residues

or green manure from crop cover. In addition, during strip till, the fertiliser is dosed precisely into the soil layers, under the seeds.

WASP is a unit mounted on the rear three-point hitch of a tractor, with an option of aggregating a seed drill with it.

Read more

The subsoiler with hydraulic protection with a gas accumulator and a breakaway accumulator is designed to break up and loosen compacted plough pans resulting from ploughing performed at constant depths, as well as to loosen compacted subsoil resulting from heavy mechanical equipment running across the field surface.

Subsoiling improves air and water conditions, and facilitates fertiliser penetration into deeper soil layers.

Read more

The subsoiler is designed to break up and loosen compacted plough pans resulting from ploughing performed at constant depths, as well as to loosen compacted subsoil resulting from heavy mechanical equipment running across the field surface.

Subsoiling improves air and water conditions, and facilitates fertiliser penetration into deeper soil layers.

Read more

The subsoiler is designed to break up and loosen compacted plough pans resulting from ploughing performed at constant depths, as well as to loosen compacted subsoil resulting from heavy mechanical equipment running across the field surface.

Subsoiling improves air and water conditions, and facilitates fertiliser penetration into deeper soil layers.

Read more

The subsoiler with plow teeth is designed to break up and loosen compacted plough pans resulting from ploughing performed at constant depths, as well as to loosen compacted subsoil resulting from heavy mechanical equipment running across the field surface.

Read more

The subsoiler with Ripper teeth is designed to break up and loosen compacted plough pans resulting from ploughing performed at constant depths, as well as to loosen compacted subsoil resulting from heavy mechanical equipment running across the field surface.

The characteristic design of the grips with additional undercuts and the roller fixed to the rear part of the machine ensure more efficient grinding and mixing of harvest residues.

Read more