AGRO-OSEK s.c. Stanisław Osek, Tomasz Osek

Firma AGRO-OSEK s.c. Stanisław Osek, Tomasz Osek (wcześniej: AGROMAX s.c.) od 1989 roku produkuje maszyny rolnicze. Założycielem zakładu jest Stanisław Osek.

The name AGRO-OSEK was coined to facilitate the identification of the enterprise among others with similar-sounding names. The direct reference to the name of its owners also serves to emphasize the core values ‒ reliability, quality and integrity ‒ that we have always treated as our foundation.

We initially specialised in the production of mounted sprayers, followed by seed planters. Subsoilers were added to our product range in 2005 and trailed sprayers in 2007. In 2012, we launched the production of hydraulically folded field harrows, which have continued to enjoy particular recognition and popularity to this day. In 2013, our portfolio was extended again, this time to include heavy cultivators. We also introduced new subsoiler models with optional spike rollers, and optional smoothing harrows were added to the hydraulically folded field harrows. 2014 saw the introduction of a carrot stubble cultivator equipped with a cuttings shredder, while in 2015 we developed a subsoiler with plow teeth. In 2017, we expanded our range of subsoilers to include machines equipped with innovative Ripper teeth and a spike-and-grip roller. In 2019, we developed and launched the production of string rollers as an optional addition to our field harrows.

In response to the emerging market demand, we introduced the WASP and HORNET strip-till units in 2023. Having gathered substantial experience in producing agricultural machinery, we constantly develop new designs and production solutions. The range of machines we manufacture is constantly expanded, with particular attention to practical and convenient solutions that save time and resources. Having operated in the agriculture industry for generations, we are perfectly familiar with farmers’ needs, and all our machines undergo a series of field tests before they enter mass production. To verify how the developed solutions work in practice, we test them not only on our own farm but also on various types of soil, engaging in the entire process those farmers who are willing to try out our prototypes and novel solutions. Recently, this practical collaboration has resulted in the development of a new version of the award-winning AGROSA planter, with pepper farmers and ornamental plant nurserymen inspiring us to create new, larger cups which would make it easier to plant these crops in foil tunnels and in fields.

In developing our machines, we also cooperate with various scientific institutions. We are eager to collaborate with universities and students, as a result of which Master’s theses describing the solutions and procedures used in our company are developed on a regular basis. Before leaving the factory, all our machines undergo detailed quality checks, are assessed in terms of compliance with the Machinery Directive, and must meet all safety requirements. We use steel of the proper grade, which we obtain from reliable suppliers, so we can fully guarantee the quality of the machines that customers purchase from us. We offer full warranty and post-warranty service.

In addition to the main production, the plant provides services in the field of maintenance, repair, overhaul and modernisation of its own machines and those coming from other manufacturers.

Our products are available in wholesale and retail sale models. They are highly appreciated by our customers and enjoy popularity among buyers, both in the country and abroad. We provide our customers with professional service and advice. At their request, we can deliver our machines directly to the agreed location.

Our experienced and qualified staff, hired on a permanent basis, ensures the ultimate quality of our products and services.

In order to meet the growing demands and needs of our customers, the plant is constantly expanding and modernising its machinery park. Production technology is also subject to continuous improvement in order to better meet customer requirements and to reduce labour intensity. A main issue in implementing new investments is also to reduce the negative impact of machinery and production on both the work environment and the natural environment. With the aim of improving our operations and the quality of our products, we have implemented the Quality Management System according to ISO 9001:2015 in 2020.

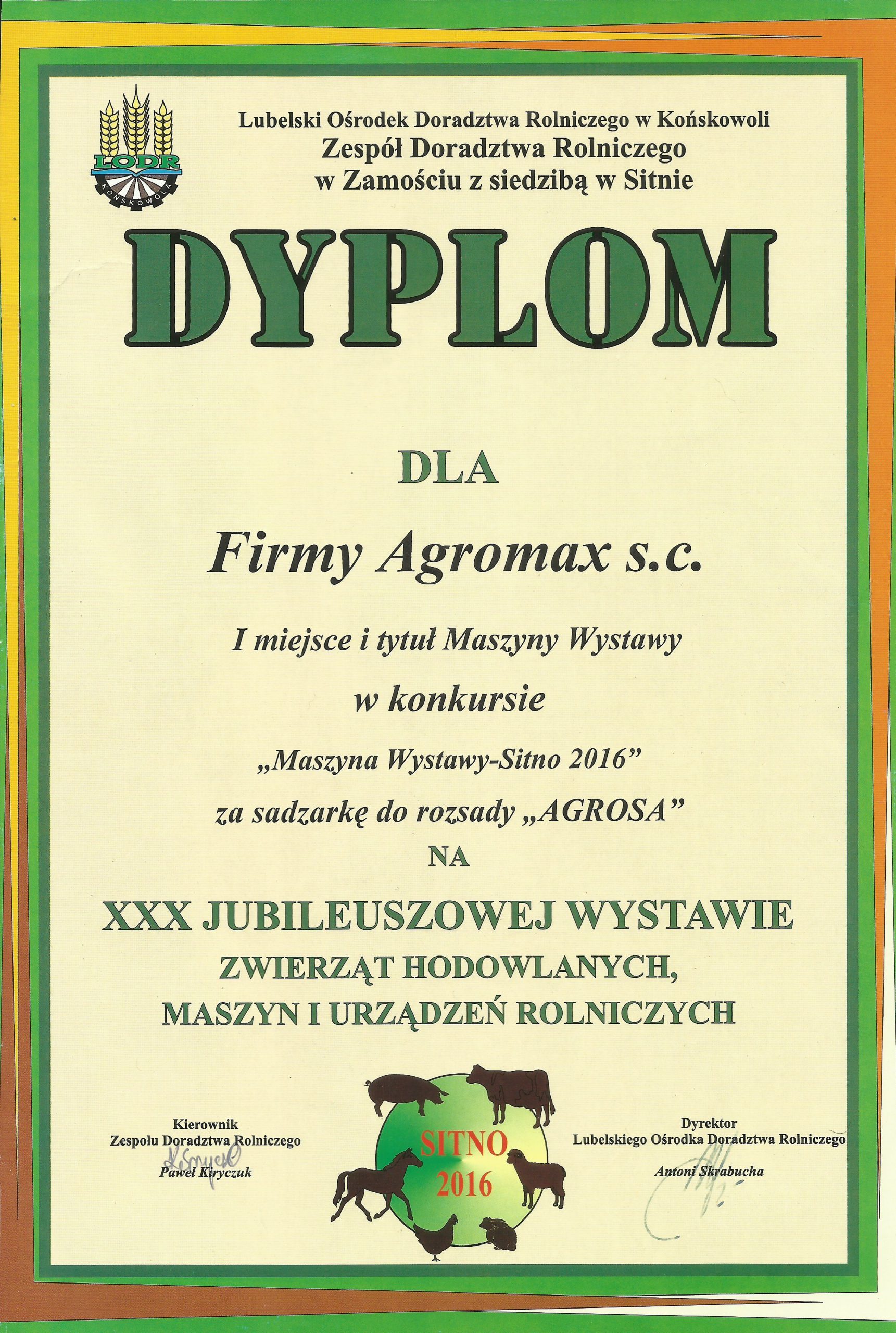

A number of awards and recognitions granted to our machines prove their highly innovative and functional character.